‘Abattoir,’ the synonym of a slaughterhouse, is a place where animals are slaughtered for food. Abattoirs play a crucial link in the meat industry, allowing the meat business operators (MBOs) to address animal welfare and food safety aspects during the process of the slaughter of animals.

Current status of slaughter operations

Currently, the slaughter operations are highly fragmented in India, especially in the rural/village areas, and tens of thousands of animals are slaughtered in unauthorized places every day by ‘meat personnel’ or ‘butchers.’ Most of such places, however, handle only one or two animals in a day.

In India, the abattoir is a State subject, and many states have enacted their own regulations pertaining to the installation and maintenance of slaughterhouses, though the extent of enforcement is questionable. As a consequence of these regulations, major cities and towns in most of the Indian States have established ‘municipal slaughterhouses’ with the purpose of providing hygienic meat to their citizens.

Most of such slaughter units were established under the administrative control of respective Veterinary Departments or related public sector institutions. However, despite having adequate infrastructure, the numbers of animals slaughtered in such units in many places are very minimal, and even there exist units that don’t even slaughter a single animal per day.

This doesn’t mean that the slaughter of animals is not happening in these places. As mentioned above, clandestine slaughter is prevalent, and animals are regularly slaughtered in unauthorized places with no provision for addressing animal welfare and food safety.

The question here is, “Does the clandestine slaughter happening in many places attributes only to the lack of enforcement of rules and regulations?” The simple answer is ‘NO.’ The possible reasons – Indian livestock production is characterized by ‘production by masses’ compared to ‘mass production by few’, as happens in many of the developed nations. In addition, a large majority of meat consumers in the country prefer ‘hot meat’ instead of chilled meat. Again, the reasons are many and better to discuss separately, as it is not in the ambit of the theme of this article.

Coming back to the topic, having highly fragmented livestock production and meat shops present in every nook and corner, one could easily figure it out that the concept of ‘municipal slaughterhouse’ does not hold good in most part of India, especially in the rural/village areas. In order to materialize hygienic slaughter process, the meat personnel/ butchers in such places have to transport the animals to faraway located ‘municipal slaughterhouses’ to get the slaughter done, which in turn requires additional investments with respect to time, money and manpower, which may not be feasible for a person who handles only one or two animals per day.

To circumvent such situations, most of the butchers prefer to slaughter their animals in isolated open places by crude methods, mostly under unhygienic environments, resulting in compromising animal welfare aspects and distributing contaminated meat to the consumers. Proper management of waste arising from such slaughter operations is also highly neglected, which in turn results in increased chances of spreading diseases.

The wet and hot meat markets are also highly decentralized in most parts of the country, resulting in the sale of meat at every place, mostly under open conditions. Such sale points completely lack even the basic facilities to ensure meat hygiene and consumer safety.

On the other side, consumers are always looking for good quality meat, processed in a neat and clean environment. It should be safe for human consumption. To achieve safety, slaughtering of animals should happen inside the slaughterhouses, which are having the essential facilities.

The requirement

As mentioned above, Local Government Institutions (LGIs) (e.g., Panchayats) are responsible for the construction and maintenance of slaughterhouses and for ensuring the distribution of good quality meat to the people. A possible solution is if the LGIs could provide a common/service slaughterhouse in every market place and if it could be made use by the local meant vendors, it will ensure hygienic meat production and proper waste management at the lowest cost. It will also be a practical approach, as slaughter is being done by meat vendors in most parts of the country, which are intended for sale by themselves through local meat stalls.

It is very clear that every LGIs can’t afford huge amounts to construct and operate large abattoirs with mechanization. The question now is, “How small can an abattoir be built?”

According to the Bureau of Indian Standards (BIS) classification, the smallest category of an abattoir is ‘small scale’ ones, which handles less than 50 large animals or 300 sheep and goats per day. But in reality, the number of animals that need to be slaughtered in the majority of the places will be much lower than this, say five or so, per day. This point towards the need for establishing multiple numbers of small abattoirs instead of one or two big abattoirs. Such abattoirs can be installed in every market places and can have a throughput capacity of fewer than ten animals per day and at a minimal possible cost.

The solution

In this article, the model of a very small, say it ‘micro’ or ‘tiny’ abattoir is considered, which can handle less than ten animals per day. It is envisaged principally as a service facility offered by LGIs to the meat vendors in a locality/market to slaughter their animals on a daily basis or market day basis.

The design and operation of all types of slaughterhouses in India are covered by the Food Safety and Standards Authority of India (FSSAI) and BIS. The licensing agency is FSSAI, and a plant is licensed to a nominated Food Business Operator (FBO), who is responsible for running the plant in a hygienic manner using Hazard Analysis Critical Control Points (HACCP) and Good Manufacturing Practices (GMP) based approaches.

All abattoirs, whether large, small, or tiny/micro, have to operate based on the same standards. At the same time, no plant will be issued a license by FSSAI based on its structural design as such, but rather on how the design allows its efficient and hygienic operation. This allows flexibility in designing abattoirs, and the case of tiny/micro abattoirs are not exceptional. In other words, the flexibility allows one to design and develop abattoirs that are fit for the purpose, but without compromising the basic hygienic principles.

A model design

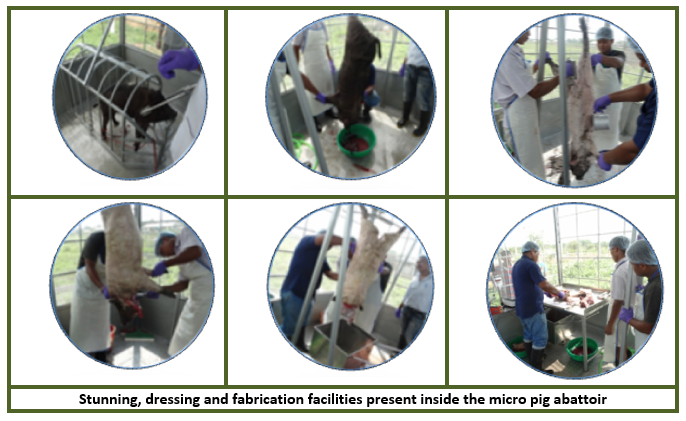

The design of a micro abattoir for slaughtering pigs is being discussed as an example. The design could meet the current regulations of FSSAI, i.e., has necessary facilities for electrical stunning, raised bleeding and dressing operations, mechanical carcass splitting, waste management provisions, etc. Such a plant could slaughter one to ten pigs per day, but one pig at a time.

Ideally, minimum land shall be made set apart for the construction of micro abattoirs. The land selected should be preferably level and dry so that construction and waste disposal costs can be minimized. Road connectivity is essential for the transportation of animals to the unit and meat and other items back. It is better to construct the micro/ tiny abattoirs in the market/ near to the market as it will help the vendors to do the slaughter as well as the sale of meat with maximum comfort.

An ideal way of construction of such micro abattoirs would be using a steel framework set into a concrete slab. The outer wall could be of solid material up to 3 feet height (e.g., thick aluminum/ steel sheet or brick), grills, or corrugated steel sheets thereafter. The roof could be constructed of similar corrugated steel sheets.

Internally, there could be provisions for stunning (e.g., electrical stunning), raised bleeding and dressing rails, table with stainless steel tops and thick nylon cutting pads for carcass fabrication etc. The floor surface shall be made of non-slippery materials, which could be laid onto the concrete floor. Bleeding/ dressing rails could be fixed on steel or concrete posts anchored into the concrete floor. The height of the building will depend on the species that it is designed to kill (e.g., 10 -12 feet height for pig abattoir).

Effective waste management has to be planned to reduce the environmental problems associated with abattoirs. The strategy to be followed in micro abattoir units is to reduce the waste by segregating resources from different types of wastes generated during the slaughter operations. Solid waste is the main waste expected, which can be divided into edible and inedible groups. About 15 kg of solid waste is expected from the slaughter of one pig. Thus, one could expect a maximum of 150 kg of solid waste from micro abattoirs per day if vendors go for the maximum throughput capacity, i.e., ten pigs/ day.

The most widely used technologies for treating solid wastes are composting and bio-methanation. Further, to treat the liquid waste arising from the micro/tiny abattoirs, a pre-filtration system combined with a septic tank and soak pit will be sufficient. The advantage is that both the solid and liquid waste treatment systems could be established very near to the site of the abattoir and are cost-effective.

The entire structure could easily be accommodated in a 25’ x 20’ area if designed properly. Also, the structure, along with the essential equipment, could be constructed with a budgetary outlay of Rs. 7-8 lakhs. The low cost, combined with minimum space requirement, makes this model an affordable structure for all the LGIs. By establishing such low cost yet practical tiny abattoirs in the market places and strictly enforcing the ban on unauthorized slaughter operations, LGIs could ensure safe and wholesome meat to the people.

Micro pig abattoir designed and established by ICAR-National Research Centre on Pig

Micro abattoir and the private sector

Pig farming in India has witnessed tremendous changes during the past five years. During this period, considerable numbers of commercial pig farms, with each one having a capacity of over 250 numbers of pigs, were established across the country. The States where the maximum surge in such farms observed are Karnataka, Tamil Nadu, Kerala, Punjab, Uttarakhand, Uttar Pradesh, Delhi, Rajasthan and some parts of North East India, especially the State of Assam.

Some of these farms are also exploring the option of venturing into the ‘farm to fork’ concept by creating their pork brands. The model of micro/tiny abattoir discussed above will be a befitting one for such units, wherein they could be able to follow hygienic slaughter operations and supply clean and wholesome pork to the customers. Moreover, following scientific slaughter and further processing operations in an abattoir could definitely help these firms to establish more credibility for their brands among the customers.

Conclusions

Micro/tiny abattoirs could support local production of food, benefitting animal welfare with shorter journeys/ food miles and enabling vendors to carry out hygienic slaughter operations, and providing clean and wholesome meat to the people. Micro abattoirs could also build trust in the local community between the livestock producers, processors, retailers, and consumers.

Citation:

Thomas R – ‘Micro’ or ‘Tiny’ abattoirs: A practical solution to accomplish hygiene and food safety in the wet and hot meat markets of India. The Vet Helpline E-magazine, Category: Innovation, Technology and Food processing, Vol VIII (2020) ISSN 2454-9282